Recently we released our Climate Policy, which is an unequivocal and public commitment to our employees and customers to understand and mitigate climate change impacts across all areas and activities of our business.

To that end, we’re currently developing a pathway to Net Zero emissions, which includes carbon reduction initiatives aligned with the goals of the Paris Agreement and the 1.5-degree global target.

We’ll be taking a multi-pronged approach that includes training and educating our people to build awareness and capability to manage climate risk, working with our supply chain partners, and embedding new best practice technologies and solutions (such as renewable energy options and transitioning of our vehicle and plant fleet to electric).

It’s a journey we’ve well and truly started. For example, we’ve developed in-house tools that will enable us to measure embedded carbon on our projects, so that during the tender phase we not only cost plan but also ‘carbon plan’ to bring a balanced solution to our customers.

Martin Smith, Group GM for Health Sustainability and Climate, says John Holland is taking a deliberate and meticulous approach to our planning for carbon reduction.

“We want to ensure our goals are achievable and our contribution genuine and sustainable – that’s what our customers and employees want and expect,” he says.

In 2021, John Holland drew a line in the sand when we successfully negotiated a sustainability-linked bonding facility with a syndicate of banks and insurance companies – the first of its kind in Australia. The cost of drawing on this facility is tied directly to our performance against four sustainability KPIs (energy efficiency, use of renewable fuels, safety culture and social procurement).

“In simple terms, if we meet or exceed the KPIs, we pay less; if we do poorly, we pay more,” Martin says. “It’s a demonstration of the strength of our commitment to a range of health and safety performance goals, not just climate. We’re literally putting our money where our mouth is.”

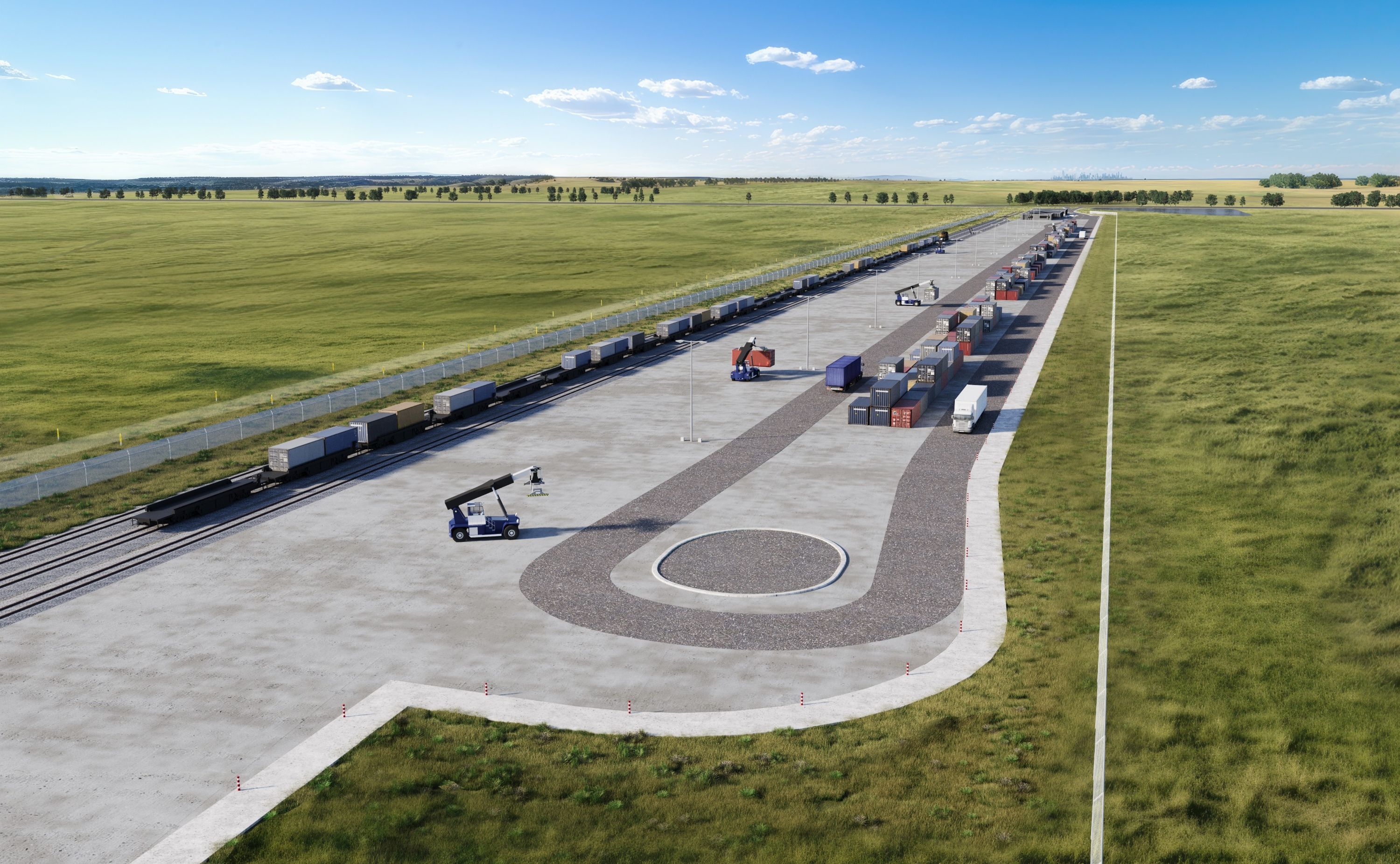

Image: At remote Oodnadatta, we’re currently delivering a desal plant for SA Water. To reduce the number of road trips (and associated carbon emissions) transporting materials to site, the plant itself was assembled off-site in a container and delivered in a single journey.